Thermoplastic honeycomb composite board

Thermoplastic honeycomb panel is a sandwich structure panel composed of continuous fiber reinforced thermoplastic unidirectional tape orthogonal composite as a reinforced skin, honeycomb core as an intermediate core material, and composite by hot pressing. Typical end uses include the automotive industry, household appliances, transportation, sports equipment, etc.

Key words:

Thermoplastic honeycomb composite board

Classification:

Thermoplastic honeycomb panel is a sandwich structure panel composed of continuous fiber reinforced thermoplastic unidirectional tape orthogonal composite as a reinforced skin, honeycomb core as an intermediate core material, and composite by hot pressing. Typical end uses include the automotive industry, household appliances, transportation, sports equipment, etc.

Product Features

1. Light weight

PP honeycomb board due to the special honeycomb structure, the density is relatively small, the weight is very light; the use of PP honeycomb board material manufacturing body, can greatly improve the truck load weight ratio;

2. High strength

Impact resistance, both rigid and flexible, can resist physical stress impact and damage;

3. Easy to assemble

Assembly is very convenient, low cost, can be assembled with screws, hollow rivets, can also be bonded or hot melt welding;

4. Waterproof and moisture-proof

This is the unique difference between PP honeycomb board and wood board. This material has good sealing performance, does not leak water, and does not absorb water even if the surface is damaged;

5. Strong weather resistance

PP honeycomb board is a glass fiber reinforced thermoplastic material, the use of a larger temperature range, between -40 to +80 degrees Celsius;

6. Strong resistance to chemical attack

PP honeycomb panel has high corrosion resistance to grease, salt water and common chemicals.

7. The product is environmentally friendly and recyclable.

Product selectable parameters

● PP honeycomb core density: 80~140kg/m

● CFRT laminate skin layup: 2-4 layers

● Plate thickness: 8mm ~ 40mm

● Plate width: ≤ 3000mm, length is not limited

● Color: regular natural color and black, other colors can be customized

● Surface customization: anti-aging film, PET non-woven fabric, non-slip surface, etc.

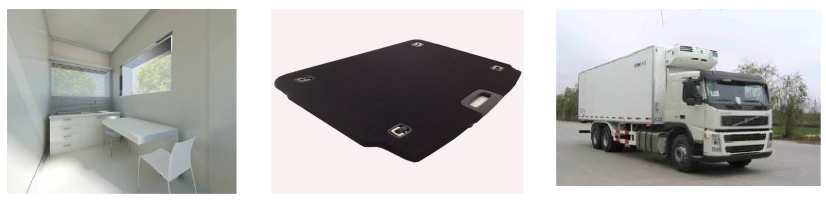

Product use: van siding and floor, scaffolding pedals, building templates, etc.

Storage

In the absence of special requirements, the product should be stored in a dry and cool place indoors.

To ensure safety and avoid damage to the product, the stacking height of the pallet should not exceed three layers. When stacking two or three layers high, the requirements

Move the upper tray correctly and smoothly.

Packaging Information

Using kraft paper, wrapping film, tray packaging;

Product Application

Technical indicators

|

Serial Number |

Test Item |

Test standard |

Unit |

Test data |

|

1 |

Thickness (mm) |

/ |

mm |

10±0.5 |

|

2 |

Area weight (kg/m²) |

/ |

Kg/m² |

≤ 3.72 |

|

3 |

Roller peel strength (N) |

GB/T1457 |

N |

≥ 180 |

|

4 |

Compression strength |

GB/T 1453 |

MPa |

≥ 1.5 |

|

5 |

bending strength |

GB/T1456 |

MPa |

≥ 11 |

Related Products

Online Message

Welcome to leave us a message, we will reply to you as soon as possible

Language selection

Language selection